Signify launches tailor-made 3D printed professional luminaires

(Netherlands) – Introduction of 3D printing facilities part of wider effort to reduce carbon footprint.

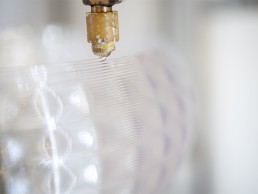

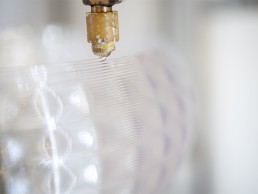

Signify has unveiled facilities to 3D print light shades and fittings in the Netherlands, and announced plans to establish 3D printing factories in the US, India and Indonesia.

By using this highly flexible, more sustainable form of manufacturing, which uses a 100% recyclable polycarbonate material, it allows luminaires to be bespoke designed or tailored to customer’s exact need, and then recycled at the end of their life, supporting a circular economy.

The investment in 3D printing underlines the company’s commitment to reducing customers’, and its own, carbon footprint; a typical manufactured luminaire (excluding electronics and optics) has a 47% lower carbon footprint than a conventionally manufactured metal luminaire, and nearly every component can be reused or recycled.

“We are the first lighting manufacturer to produce 3D printed luminaires on an industrial scale, reinforcing our position at the forefront of lighting and sustainable innovation,” said Olivia Qiu, Chief Innovation Officer at Signify. “Printing luminaires provides a more flexible, fast and more environmentally friendly way to manufacture. We can create new, or customise existing designs, that fulfil customer needs quickly without huge investments and long development cycles.”

Signify already has a 3D printing facility at Maarheeze in the Netherlands. It aims to have up to 500 3D printers of different sizes, with the ability to create luminaires up to 60cm in height and width. In January 2020, new Signify 3D printing facilities will be operational in Burlington, MA, USA, serving both professional and consumer markets. Additional facilities in Noida, India and Jakarta, Indonesia, will follow shortly after. LED lights will be integrated into the luminaires at all of these sites.

The move has already received support from fashion and food retailer Marks & Spencer (M&S), which has announced that it is in the first phase of rolling out thousands of 3D printed luminaires across stores in the UK as part of a wider move to improve store performance and generate significant energy savings.

Oliver Knowles, Research & Development Manager within the Property Group at M&S, said: “3D printing has been around for a while, but these luminaires are the first real retail lighting application we’ve seen that improves the sustainability of our stores and are extremely complementary to our sustainability strategy. The potential for these fittings is enormous, both from an energy and cost-efficiency perspective.”

Signify has also announced the rollout across Europe of the world’s first online service to enable consumers to tailor decorative luminaires.